THE DIFFERENCE BETWEEN AISI 410 STAINLESS STEEL AND SS 410

AISI 410 STAINLESS STEEL,SS410(UNS S41000)

AISI 410 stainless steel is one of the most commonly used martensitic stainless steels. It contains approximately 12% Cr and therefore has moderate corrosion resistance. Unlike austenite (e.g., AISI 304 and AISI 316), martensite (e.g., grade 410) is magnetic and can be hardened by heat treatment such as carbon steel and low-alloy steel. SS410 has excellent mechanical properties such as tensile strength, creep and fatigue strength and is mainly used in steam turbines, jet engines and gas turbines.

The Type 420 is basically a high-carbon version of the SS410, providing higher strength. Ferritic stainless steel 430 has a high chromium content and therefore has high corrosion resistance.

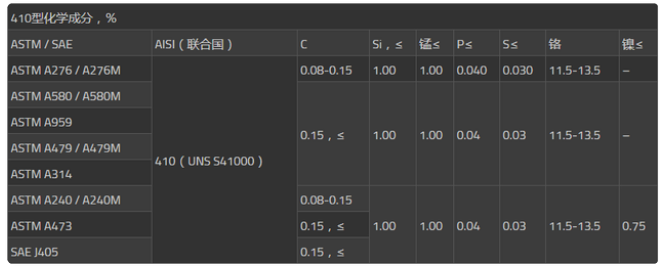

AISI 410 Stainless steel composition

- ASTM A276 / A276M: Standard specification for stainless steel bars and profiles

- ASTM A240 / A240M: Chromium and Inconel stainless steel plates, plates and bands for pressure vessels and general applications

- ASTM A580 / A580M: Stainless steel wire

- ASTM A479 / A479M: Stainless steel rods and shapes for use in boilers and other pressure vessels

- ASTM A959: Standard Guide for Specifying Harmonized Standard Grade Components for Wrought stainless Steel

- ASTM A473: Stainless steel forgings

- ASTM A314: Standard specification for forged stainless steel billets and rods

- SAE J405: Chemical composition of SAE forged stainless steel

Application

410 stainless steel is the basic general purpose steel for steam valves, tray valves, pump shafts, turbine blades, bolts, and other parts that require corrosion resistance and strength of 540°C (1000°F).